Pipelines are getting closer every day to the end of their design life. Typically, entire pipeline systems do not fail all at once even when stretched beyond the design life. More commonly, sections of pipe or maybe even single points will break resulting in costly repairs. Budgets are not large enough to replace entire systems so it is essential to perform proactive leak detection investigations on a regular basis to find leaks before they become emergency situations. EnTech® combines modern technology with traditional leak detection methods for a trusted approach that provides flexibility and adaptability to the challenges of leak detection in different municipal, commercial and industrial environments. Our service offerings can help eliminate emergency repair costs to maintain planned budgets for a no surprise asset management approach.

According to the ASCE there are an average of 240,000 water main breaks that occur each year across the nation. Many of the main breaks could be prevented with proactive leak detection programs that inspect the entire system on a regular basis. Not only do main breaks cause large water losses they are also costly to repair: ~5-10 times more expensive than a scheduled maintenance repair and that is not including damage done to surrounding properties. Utilities require a thorough assessment of their water pipeline infrastructure to maintain their water efficiency. We are able to identify and prioritize problem areas in your infrastructure using a leak detection system that applies cutting edge technology coupled with traditional techniques to assess all water lines regardless of size or material. EnTech® can help you meet your water sustainability and efficiency needs.

Pipeline leaks on commercial properties can result in high dollar damage to assets and high utility bills. Depending on the utility practices, the owner of the property may be responsible for all pipelines on their side of the meter. If these leaks don’t surface they can be hard to pinpoint and you have to pay for all or partial amounts of the bill. EnTech is able to identify and prioritize problem areas in your infrastructure using a leak detection system that applies cutting edge technology coupled with traditional techniques to assess all pipelines regardless of size or material. EnTech® can help you meet your sustainability and efficiency needs.

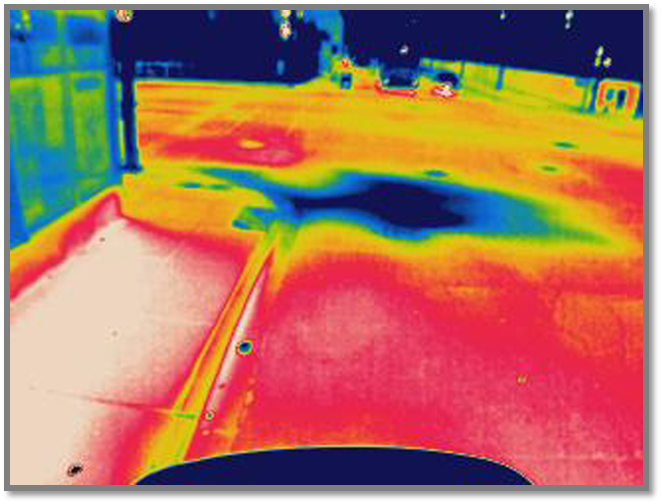

Hazardous materials inside pipelines or tanks sometimes leak. When this occurs the leak needs to be stopped as soon as possible and the soils surrounding the area need to be remediated. Typically multiple tests are necessary to determine that there is a leak and to measure the extent of the plume created. EnTech®’s Infrared - Energy Pattern Analysis (IR-EPA) leak detection system is able to identify leaking hazardous materials and map the extent of the plume in a single deployment.

Chilled systems are essential for keeping large buildings in downtown areas cool during the summer. In order for a chilled system to maintain this level of efficiency there must be a proactive leak detection process to identify problems in a timely manner. EnTech® is able to identify and prioritize problem areas in your infrastructure using an Infrared – Energy Pattern Analysis (IR-EPA) leak detection system before they turn into emergency issues. We can help you meet your sustainability and efficiency needs.

Dielectric oil is essential for keeping certain underground, high voltage cables cool to carry electricity at an efficient level. If leaked into the ground, the oil can contaminate soils and groundwater causing costly cleanups. Leaking oil must also be added to the closed loop systems so that the temperature of the cables can be maintained. EnTech®’s Infrared – Energy Pattern Analysis (IR-EPA) leak detection system can help you regularly monitor your dielectric oil system for leaks so that they can be repaired before a costly failure.

In industrial plants, proper fire protection is an essential element and is often required before new units can be brought online. Due to the high pressure and noise from surrounding equipment it is often very difficult provide proactive leak detection on firewater systems with traditional acoustic leak detection equipment. EnTech® has the ability to provide leak detection services in high noise areas because our Infrared – Energy Pattern Analysis (IR-EPA) does not depend on the ability to listen for a leak. IR-EPA lets us “see” beyond the surface.

Fuel Pipelines are critical infrastructure at airports and military bases. Fuel pipeline leaks are not only costly because of lost fuel but they are also detrimental to the environment. Operators require a thorough assessment of their fuel pipeline infrastructure to maintain efficiency. EnTech’s proactive leak detection approach can help you manage your pipelines on a budget with no surprise emergency failures.

Pipelines are critical to industrial processes. Without the ability to carry raw materials into the plants, move partially developed products, and completed products around the plant it becomes increasingly difficult to produce at a profit. EnTech® ‘s cutting edge Infrared – Energy Pattern Analysis (IR-EPA) leak detection techniques can help you proactively maintain your pipelines within a budget and eliminate emergency leaks that can be very costly both in repair and lost production.

Government agencies are cracking down on plants that do not take the proper measures in disposing of their waste. Industrial plants are subject to agreements much like municipal sewers in regard to inspecting and repairing sewer pipelines. These agreements often stipulate that millions or billions of dollars are spent to identify points of improper disposal and eliminate them. EnTech®’s patented approach is a complete solution that combines Infrared – Energy Pattern Analysis (IR-EPA) with Ground Penetrating Radar (GPR) and insitu grouting repair methods for trenchless remediation, including repeatable documentation to ensure that the agreements are met.

Sewer management is crucial to the sustainability of life. It is necessary to properly discharge wastewater clinically and efficiently. Failure in wastewater systems will cause major implications in the future. The population is increasing, and larger volumes of wastewater put additional strain on existing sewer infrastructure. Each year there are nearly 75,000 such overflows in the United States, discharging approximately 900 billion gallons of untreated sewage into lakes, streams, and rivers. This affects our drinking water, which in turn affects human habitation. The Clean Water Act of 1972 is a Federal Law that regulates and governs water pollution in the United States. It expects public utilities to properly treat and discharge water.

Sewer owners need a reliable and cost-effective way of inspecting wastewater systems to make sure they are in compliance with federal regulations. EnTech® improves the integrity of your waste water collection systems using its patented leak detection and mapping technology. This provides sewer owners with a non-destructive means of assessing the condition of their wastewater collection systems.

Steam systems are essential for keeping large buildings in downtown areas warm in the winter. In order for a steam system to maintain its level of efficiency it must have proactive leak detection to identify problems in a timely manner. EnTech® is able to identify and prioritize problem areas in your infrastructure using an Infrared – Energy Pattern Analysis (IR-EPA) leak detection system before steam leaks turn into emergency issues. We can help you meet your sustainability and efficiency needs.

The EPA estimates that ~569,000 Underground Storage Tanks (USTs) nationwide store petroleum or hazardous substances. The greatest potential threat from a leaking UST is contamination of groundwater. Once a release event has occurred it is imperative that soils be remediated so that groundwater resources are protected. To determine the best method for soil remediation a site assessment is often required. EnTech® has written industry standards for non-destructive brownfield testing methods to map plumes. The combined Infrared – Energy Pattern Analysis (IR-EPA) and Ground Penetrating Radar (GPR) approach identifies a release event and maps the extent accurately and efficiently.